Now that the water is in your tank, how do you get it out so you can use it?

We could hook the tank up to the regular water tanks pump, but what if something we don't like got into the rain water tank? How would we get rid of it without contaminating the rest of the tanks?

The simple idea of having a tank full of rain water quickly became a concern about damaging the rest of our water supply. The decision was made that the rain water tank needs to have a purge hose that we can drain its contents should we decide that it has become compromised. I thought about making a very complicated valving system where water from the rain tank could be tested and purged if desired without going into the main tanks or, by opening some valves, used in conjunction with the rest of the water tanks. This idea, while complicated, seemed like an adequate solution.

The only caveat with this plan has to do with the flexible water tank and its durability. Flexible water tanks are a great way to get water tankage into small nooks in the boat where a regular tank would be difficult to install or fit. The problem with flexible water tanks stems directly from this flexibility.

As the yacht bounces around in the seas, the water inside the tank will slosh around. In a rigid tank, the contents move while the tank remains un-phased. In a flexible tank, the contents of the tank move along with the tank. This constant sloshing will wear on the seams of the tank and lead to the eventual death of the flexible water tank. It is best to use flexible water tanks only for a short period of time and then store them drained and empty while underway.

If we use the rain water tank as part of our water tanks, it will suffer greatly from constantly flexing as it is the lowest tank and would stay full the longest. The alternative is to fill the tank with rain water and drain the tank instantly into the other water tanks through a hose with its own pump.

This would satisfy all the needs we have placed upon the flexible water tank. It would allow us to test the water, purge if undesirable, and maintain the tank empty for as long as possible. We also don't have to worry about accidental contamination from the flexible tank to the other tanks because there would be no direct plumbing fitting that could be left open and cause a disaster.

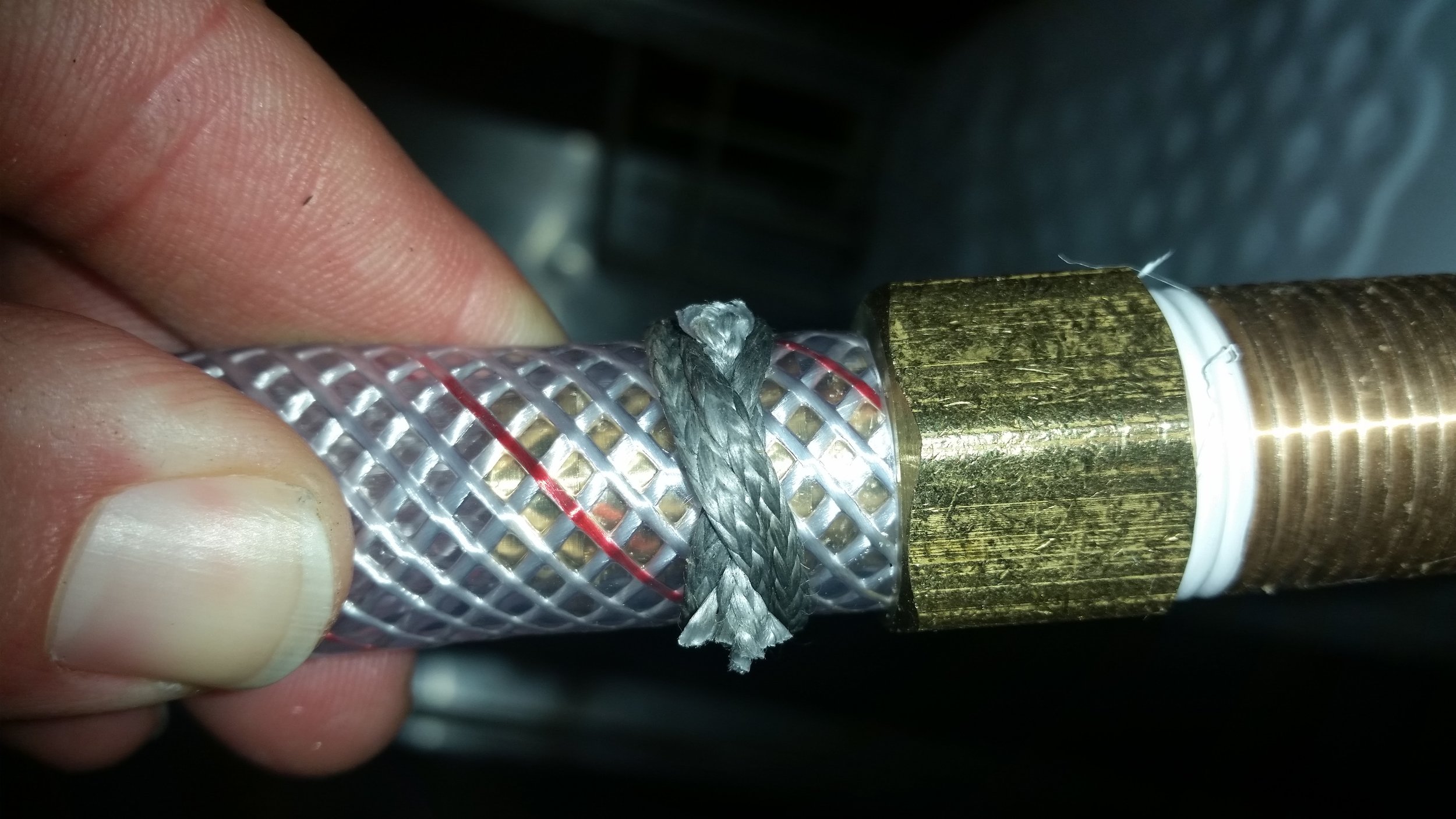

The flexible tank drains via a small 1/2 inch water hose that is led to a high powered water pump. This pump will flow 4 gallons per minute at 60 psi through a hose that will allow us to test the water, and if we like it, dump it into the main tanks. If we don't like it, we can purge it overboard or use it for showering and laundry. Best of all, it keeps us actively watching where and how much the water is going into the different tanks.