Back in February 2015, I installed dyneema lifelines. It has been two years with them in place, and it is time to see how they have been holding up.

The lengths of the lifelines are subject to chafe from sheets rubbing on them while sailing, but with proper block placement, chafe can be reduced if not removed all together. This gives us great peace of mind since we don't have to worry about corrosion nor chafe. But how have the splices been holding up?

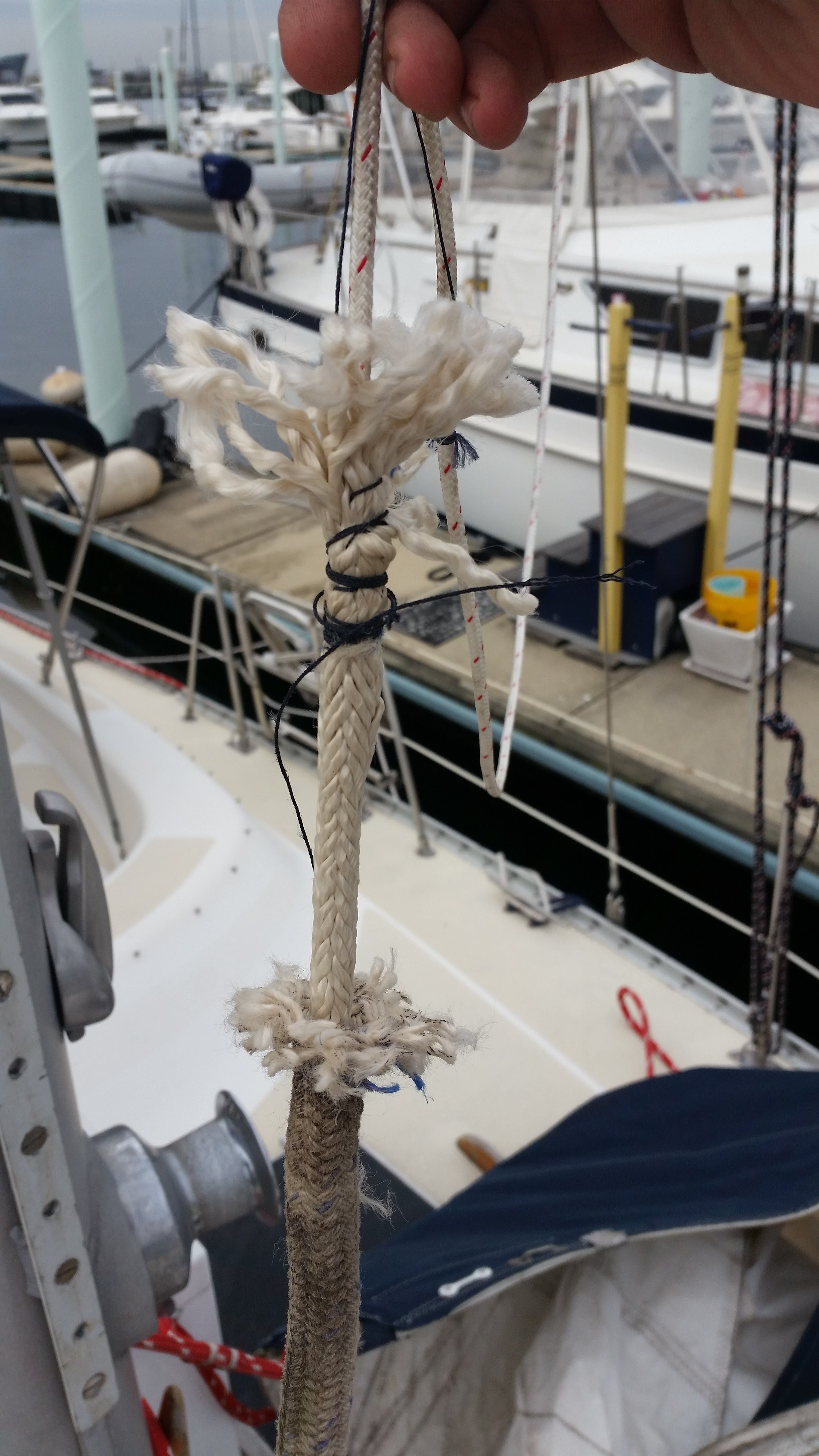

Very well! The ends of the lifelines are finished with a mobius brummel splice, forming a nice locking eye splice that will hold true and strong! This section of the lifeline looks great and the netting wrapped over the lifelines has shown no signs of chafe.

The gate stanchions were spliced rather differently. The spliced lifeline was too large to fit through hole in the stanchion, so the splice was routed along the outside of the stanchion. To allow inspection, the long bury splice was performed a considerable distance from the stanchion. This allows me to loosen the end lashings and pull the lifeline out of the stanchion to inspect. The extra distance is to allow me space to service the lifeline should the need arise.

By polishing the stanchion's holes previously, there were no sharp points or burs to chafe on the lifelines. This has granted us the joy of no serious chafe after all these years!

With the gate closed, the tension on the lifelines pulls the thimble off the stanchion and straightens everything out.

The lifelines have served their purpose very well for the past two years. There has been negligible chafe, and no corrosion. The only issue they have demonstrated is more of cosmetic concern: fading. When the lifelines were new, they had a strong electric blue color to them. Over the years, the color has slowly faded to a much more muted blue.

2015

2017

While the vividness of the blue has subsided through the years, the strength and peace of mind have not. Careful planning to reduce chafe on the lifelines will make strong, durable, and worry free lifelines possible that will last you many years.