This has nothing to do with Karma or friendships or anything like that. This is about building a battery!

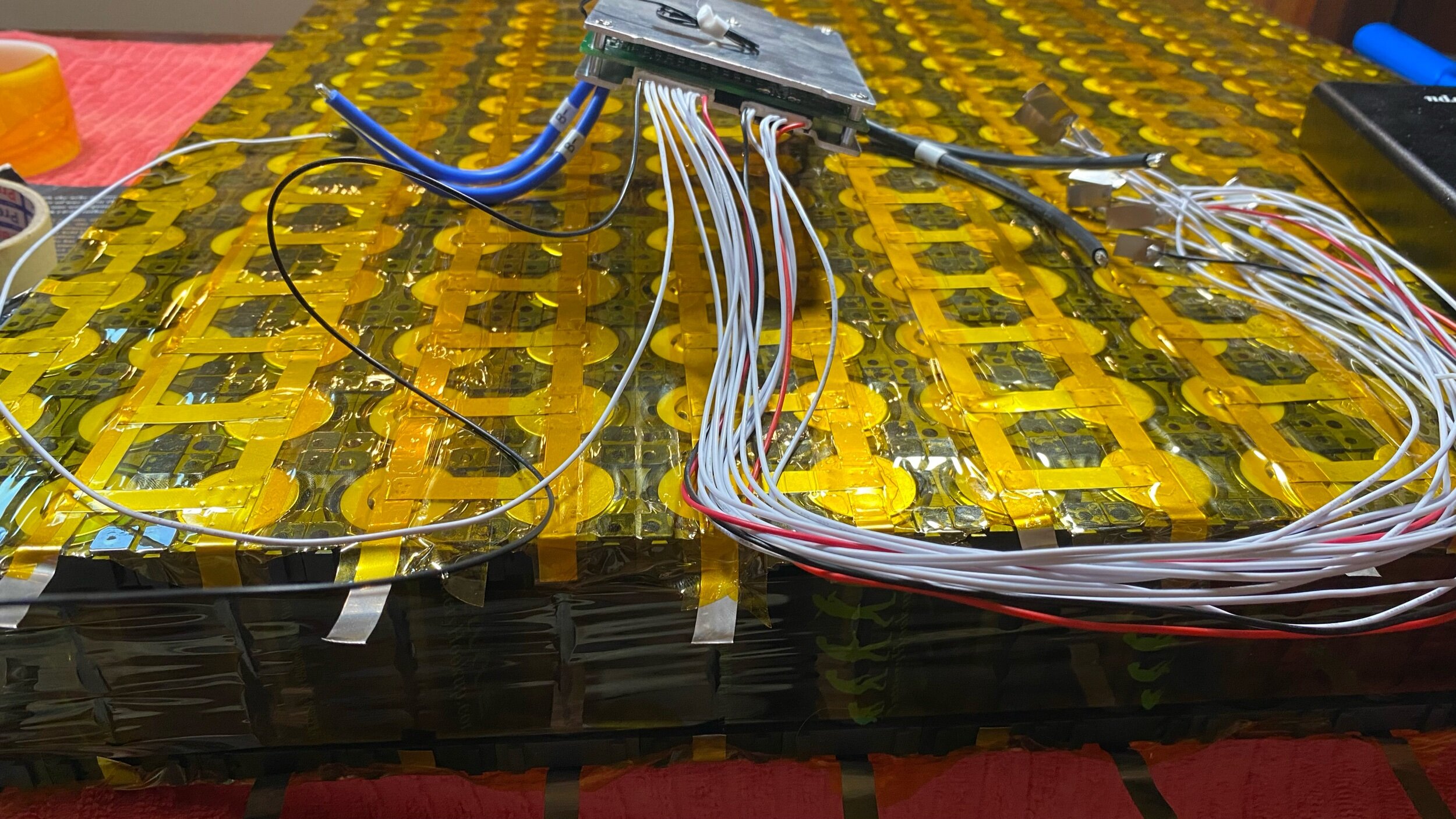

In the battery being built above, the cells are not aligned in neat and even patterns. This is due to space limitations and just makes things complicated. With a little thought, major problems can be avoided, and the implementation takes a small amount of effort.

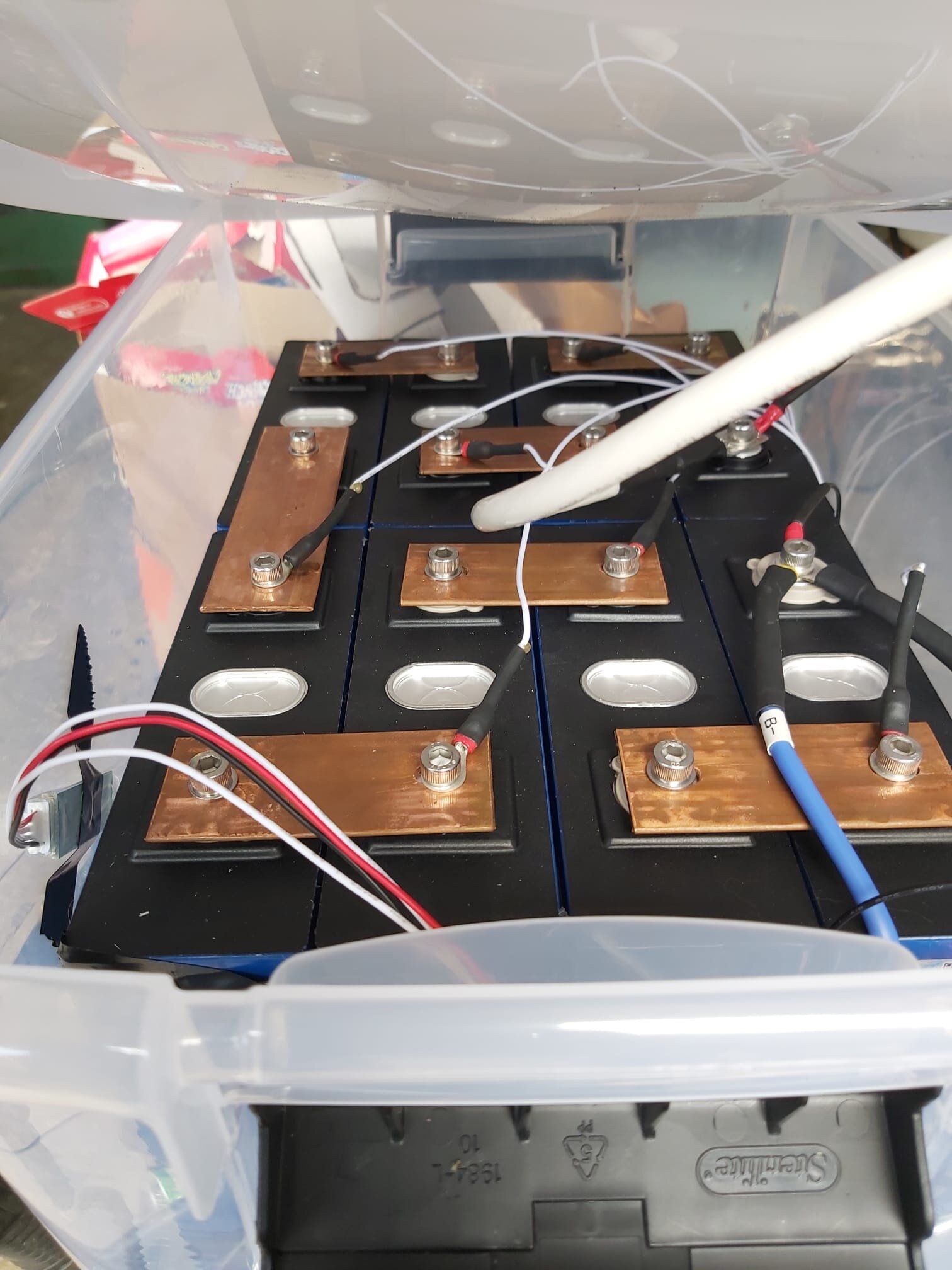

In this example, I’m building a 16s16p battery. That’s fancy talk for a 48v battery made up of a ton of tiny battery cells. Each cell is 3.2v, and when I link 16 of them up in series, I end up with 51.2v (which ironically is considered a 48v battery). Each cell is only 6ah, so if I just linked 16 of them up in series I would have a 48v battery that holds 6amps; not very useful to power the electric motor in our sailboat along with all of our house loads. To beef up the amp capacity a bit, we simply add more cells in parallel, 15 more to be precise! This gives us a battery that will hold 16x6=96 amp hours and is made up of 16 cell groups in series.

The final result is 16 series and 16 parallel, or also called a 16s16p battery.

That’s cool and all, but why do the cells need to be in strange interlocking patterns? Space. Being how these are batteries for a boat, space is never existent and we will need to cram these batteries into wherever we can fit them. We didn’t have the space to fit 16 cells in a row, so we arranged them into an arrangement that is 10 cells wide. This means that each parallel group is 10 cells in a row with another 6 cells crammed around next to them in the next row. The next row can fit 4 more cells of the next group, the following row is 10 of the same, and then 2 more cells spilling over into the next row. This pattern will continue all the way down the line until you finally get to the last cell group where the pattern just ends.

Why does this matter?

You need to know how much power you plan on pulling from your battery at any point in time and then build the battery to handle this load. In our case, the battery will need to supply 400 amps to power our electric motor when it runs at full speed. Building one battery that can yield 400 amps is pretty ridiculous so we did the logical thing of building 5 batteries that combined will yield 400 amps. Each battery only needs to do 1/5th of the work and therefore each battery will only need to yield 80 amps.

80 amps is our magical number and those pretty Ni strips we have linking the cells together can only flow 5 amps.

These 4 cells here at the end can become quite the problem! 4 cells can theoretically flow out 4/10ths of the power from the battery. That’s 32 amps that will come rushing out of those cells at full speed from the motor. If we simply connected the cells together with those strips of Ni, power would flow through the area and it would look like everything is fine.

Then when we give the engine a good bit of throttle to move us in a hurry, our battery would break! The little Ni strip that connects those last 4 cells to the rest of the battery can only flow 5 amps. When you start pushing 32 amps through it, that Ni strip will heat up and magically transform itself from a conductor into a fuse. When it gets hot enough, hopefully it will melt and sever the connection. If it remains connected and heated, it can cause the Li cells it is running over to ignite into a flame which will burn with all the fury of Hell, even submerged underwater!

The solution is very simple: Build a bridge.

The last cell will flow out the least amount of power, but the cell leading to it will flow the amount of power that it needs plus the amount of power of the cell downstream from it. The next cell over will have the same conundrum.

By stacking the Ni strips, the amp capacity of the connections increases by 5 amps at each stack. This stacking is called a “bridge” as it bridges a pass that would otherwise serve as an electrical bottleneck. This bridge stacks up to look like the silhouette of an arch bridge which will then flow the power across the gap.

It is important to remember that the bridge needs to extend out the other side in the same manner, otherwise the bottleneck simply gets transferred.

If you notice, I didn’t build the bridge up to 35 amps, but instead stopped at 20. This is because the 80 amps that will flow out of the side of the battery are being directed out through the strips that run off to the sides.

Since we need to flow 80 amps and each strip carries 5 amps, we would need 16 strips to be safe. By doubling the strips, we create a flow of 10 amps out certain cells while single strips only flow 5 amps. This area beyond the bridge only has single strips, meaning that only 20 amps will leave the battery in this area and therefore 20 amps needs to flow by the bridge.

When you build your battery, trace out how the electrons will flow along and trace out their path from the positive pole to the negative pole. If you find an area where a bottleneck exists, simply add more strips to increase the ampacity of that portion. When you build a bridge, also look at the areas that feed the bridge and extend the additional strips into those areas as well to account for the added flow of electrons in these narrow areas.