With the chines in place, it is time to attach the sheer and shelf clamp. These two strakes will tighten up the top end of the dinghy frames and make the framework look like a potential boat instead of a possible boat.

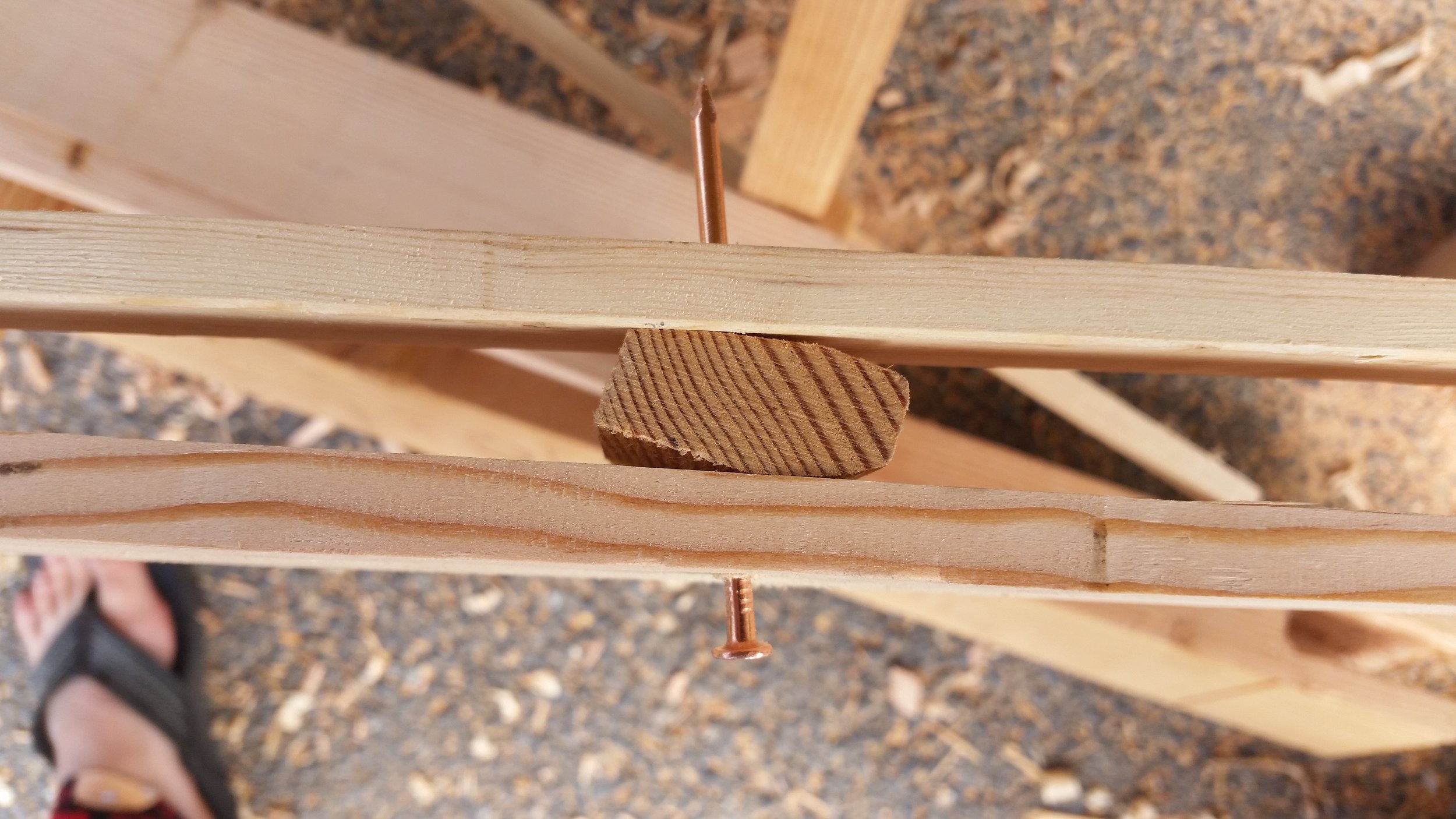

The sheer and shelf clamp need to be installed at the same time since they are riveted together. I began with the first three stations, setting the two strakes on the third station with a C Clamp to hold it in place while I worked on stations one and two. Once the first two stations were secured, I could remove the clamp as I worked my way aft.

The bend in the hull proved to resist accepting the strakes. These strakes wanted to remain straight and were not keen on being bent into shape. The downfall of these strakes is their length, providing me with the leverage I need to bend them into place and rivet them together.

Work proceeded quickly, first connecting all the sheer and shelf clamps with a single row of rivets at the top of the frames, followed by a second row of rivets to further attach the bottom of the sheer strake. The stem is still not present so the strakes are set longer than the length needed in both fore and aft dimensions.

In the end, the starboard sheer and shelf clamp were securely fastened to the frames. This solidified the starboard half of the boat and tied all the frames together. The dinghy is really beginning to look like a small boat instead of a pile of random cuts of lumber.