We have finally begun the planning process for our new dinghy. This dinghy will be stored on deck, between the mast, boom, and dodger while on long voyages. This will reduce the drag associated with towing a dinghy behind us.

Tooth is an excellent row boat, but on long trips, he can be a drag! At 13 feet long, he is too large to store on deck when sailing. This leaves us towing him along over hundreds of miles, which has led to a few snags along the way.

We are very good at dodging crab pots in the bay, but they have a way of getting hooked on the painter. The snagged crab pot will bring us to a halt until we free it from the line. A towed behind dinghy also adds resistance to the equation, making us travel along more slowly than if we were not towing. It's the same idea as clean bottom vs. dirty bottom. It might not seem like much of a drag, but its effects will add up considerably.

While the longer length allows Tooth to carry more weight and row more efficiently, we need a smaller dinghy that we can take on long voyages with us. This is where our new dinghy will come into play.

I stumbled upon a dinghy design that I really like (mostly) and plan to make only a few modifications to it. The design is rather old, appearing in an 1890 Forest and Stream. The designed skiff comes in at 8.5 feet long and 3.5 feet wide. This is close to the size I'm looking for, but still on the big side.

We have a maximum of 10 feet available on the deck, so I'm looking to occupy it with something around 7 feet long. Shortening the span between the stations will bring this boat down to size and give us the wiggle room we want and need around the stowed boat on deck.

I am also going to change it from a flat bottom to a slight Vee bottom. Tooth is a flat bottom, and Maddie and I both hate the sound of the waves slapping into it. The first time we launched it, we thought something had broken because it was so loud! To avoid having that happen again, we are going to add a bit of a Vee to the hull, allowing it to cut through the waves rather than smacking them harshly.

This design is around 126 years old, and there have been plenty of skiff designs between then and now! Why this design? Why not a more contemporary model? Most all contemporary designs are for prams (which look ugly to me) and plywood construction.

I desire something with a pointed bow, allowing us to row into surf if we need to, and a carvel plank construction using "real" wood instead of plywood. I went back in time to find plans for wooden dinghies, before playwood and "stitch and glue" had dominated the scene.

Stitch and glue construction is fast and rewarding, it's how I built Tooth; but it doesn't hold up as well as I would like it to. Tooth has had a rather rough life, being towed over 800 miles in his first year after launching. In one year, Tooth has also shown significant amounts of wear and tear.

I hope that a heavy carvel planked hull will hold up to these abuses a bit better.

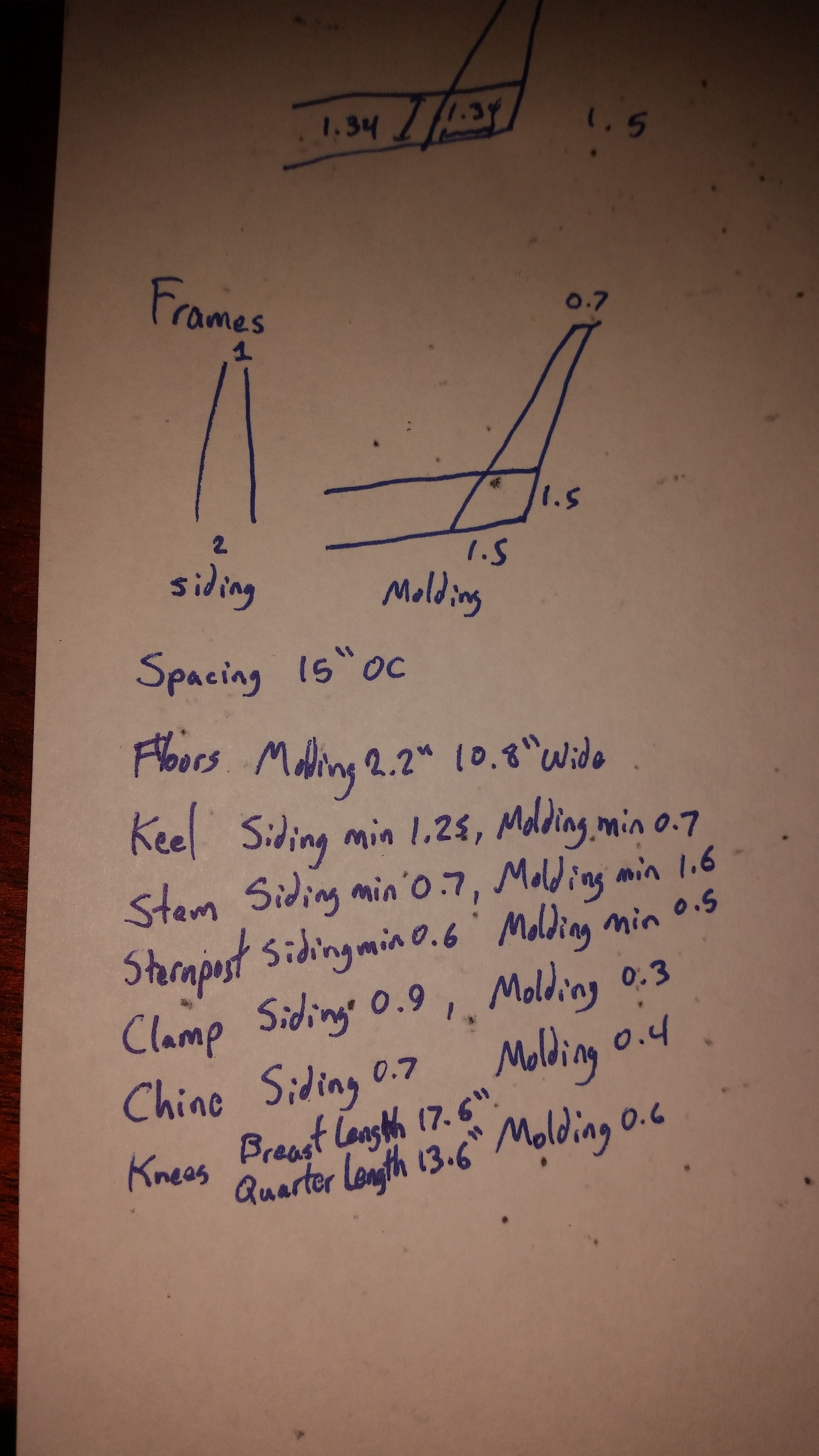

As you can see, the plans are not very extensive (that single page is what I'm going off of). There are no scantling numbers given, or diagonals or buttocks, simply a very basic line drawing with a station view.

I took to Herreshoff's Scantling Rules to calculate the needed dimensions for the parts at play. I did upsize a few of the key points (keel, frames, stem, and planking) to give me a bit more strength out of it.

With the basic calculations in place, I set out to collect some lumber to begin construction. At the moment, the plan is to build the entire dinghy out of Douglas Fir (Oregon Pine); but the planking might end up being out of cedar if I can't locate clear stock at a good price.

Since I am changing the design a bit, I'm going to begin by building a mold out of 3/4" particle board. This will allow me to visualize the hull form better (and make sure it fits in its intended location on deck) before construction begins. From the molds, I can also pick up the frame bevels by running battens along the hull, making final fabrication of the frames all the easier.

Lastly, having particle board templates of all the pieces needed will make cutting out the actual pieces from the wood all the easier. Instead of doing proper lofting, I'm going to cheat and use the mold as my templates.