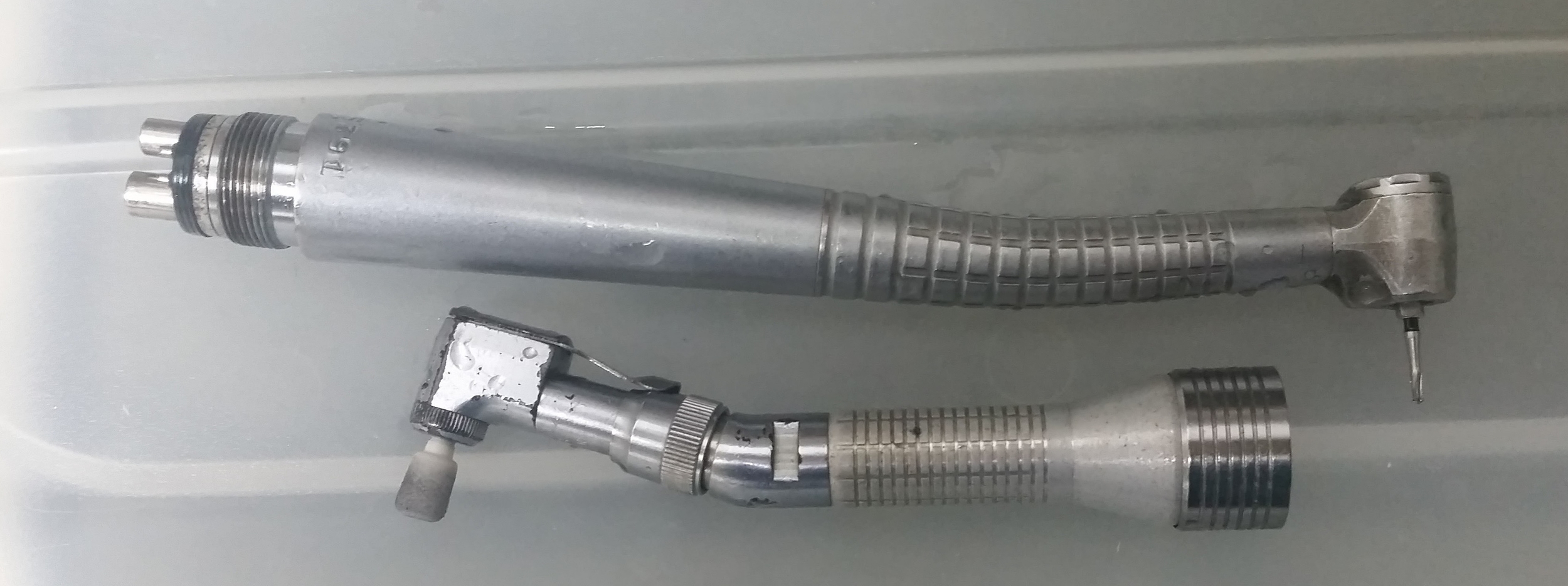

To properly radius the holes of the chainplate, I use a carbide bur in a high speed hand piece followed up with an abrasive cone in a low speed hand piece.

These burs will result in a smooth and rounded transition from hole to chainplate, reducing the risk of point loading on the fasteners near the corners.

With lots of water flowing over the work site, I am able to keep the whole system cool while rounding up the corners. After the course reduction was completed, finer polish was achieved with the slow speed hand piece, smoothing it all up. This step could also be completed using a dremel tool, but as a dentist, a drill is second nature and I know I can get the exact result that I need!

Now the chainplates are finished and ready to be installed with new hardware and beeded into the deck to seal out any water intrusion.