Osmotic blisters may be the bane of a fiberglass hull, but it is a small problem that has been blown way out of proportion. The truth is, all hulls suffer form some form of degradation: wood hulls rot and get worms, fiberglass hulls get blisters, steel hulls rust, and aluminum hulls disappear by galvanic corrosion. You simply need to choose a hull material that you feel comfortable repairing yourself.

Blisters are caused by the osmotic pressure of water that passes through the layers of fiberglass and exposes areas of delamination. When the hull is lifted from the water, these areas will bulge out like lumps. When you crack them open, water will pour out with intense pressure.

Fixing blisters can be a very costly endevour if you pay to have someone else do it, but they are actually very easy to fix yourself. You only need a grinder and an sander.

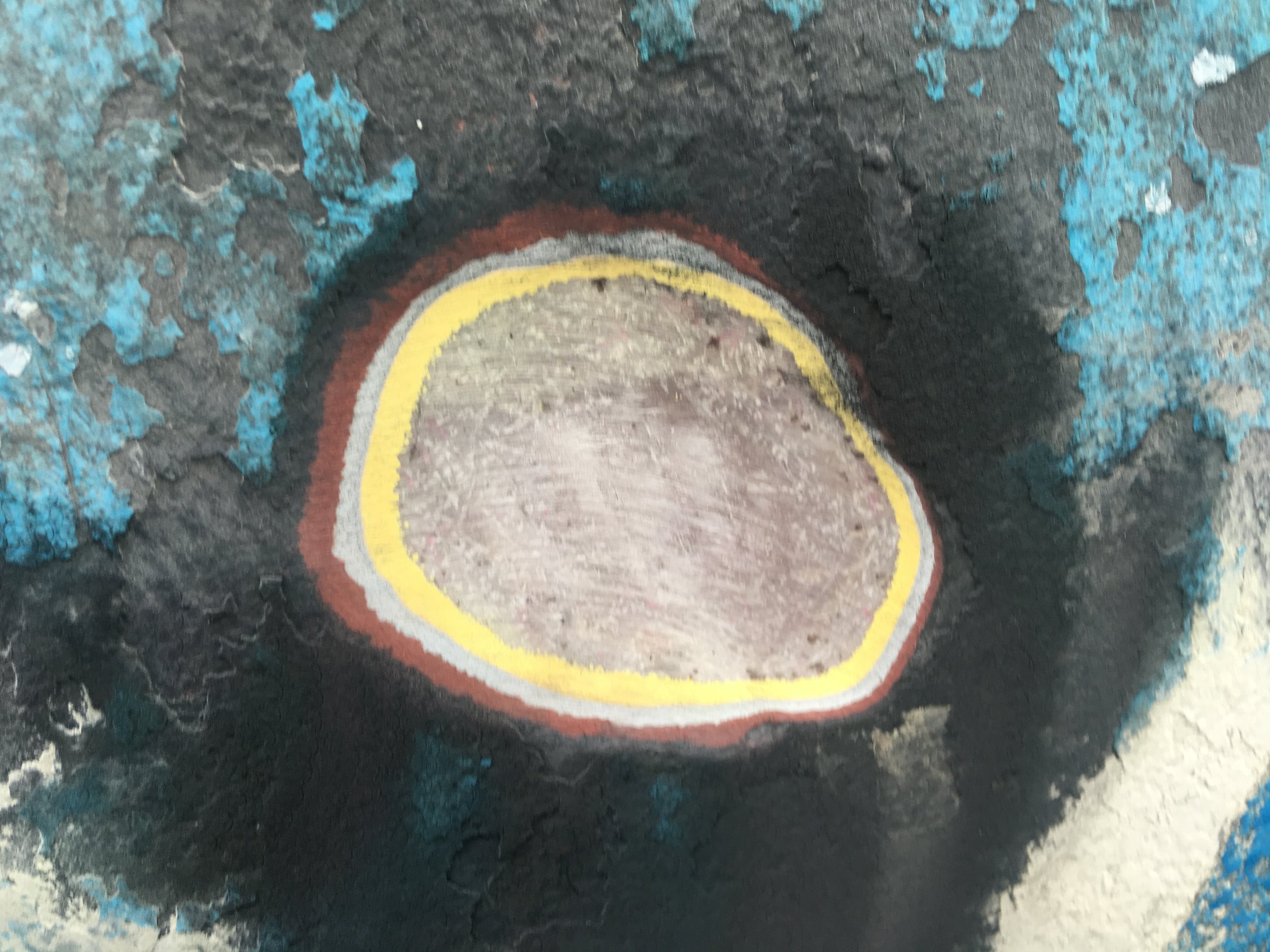

Using a grinder, you can rip through the blister, tearing out all the delaminates fiberglass that is overtop. Then you can begin to tear out laterally, as you follow the damage from the blister. As you work, the affected area will be wet and have a slight brown color to it. You simply want to grind away until you no longer see any brown or wet, and you can't even see where the different layers are of the hull.

At this point you will have a gaping hole in the side of your boat. This may seem like a major problem, but it is easy to fix.

If the blister is not too deep, the repair is very straight forward. If the blister is rather deep, then you simply need to take a few extra steps to fix it. Neither of these two methods are difficult, and both can be done in a few minutes.

If the blister is shallow, and not passing through many layers of the hull, you can simply fill the hole with thickened epoxy. How deep is too deep for just epoxy is dependent on the hull itself. If you have a 1/4 inch deep hole on a 1/2 inch thick hull, you have just compromised 50% of the hull in a blister! Yet, if the hull is inches thick, this is a small surface scratch that is inconsequential to the total structural integrity of the hull.

In my case, the hull in this area is 1.5 inches thick, and the blister was 1.4 inch deep. This comes out to be 1/6th the hull thickness, so I simply repaired it with thickened epoxy.

Regular West System Epoxy can be mixed well, then 406 thickening agent can be added until the entire mixture looks like thick peanut butter. This thick mass can then be stuffed into the hole and wiped over with a plastic spatula. The spatula will contour the blisters surface to be flush with the hull, taking all the work out of fairing the repair job! It is just that easy, simply smear it in and smooth it off!

If th blister is deep, you can wet the area with untickened West System Epoxy, and then add some chop strand mat to the hole. This will provide new fibers that will add in the structural integrity of the entire repair. Over this layer, you can then add more unthickened epoxy to fully wet the strands of fiberglass. When they are all wet, you then proceed with the thickens epoxy just like before. Simply smear it in and scrape it smooth!

Blisters may be an eyesore, but they are more an annoyance than anything else. Small blisters will not sink your boat, only it's resale value! Keeping your boat out of the water through winter allows the hull to dry out well and reduce the incidence of blisters as well. If you live aboard though, your boat will always be int eh water and blisters will become a fact of life when you haul out.

You can choose to ignore them until they get big, or you can choose to repair each and every one of them as they occur. Which ever way you choose to go with, just keep in mind that blisters are not a death sentence to a fiberglass hull, simply an annoyance you get in response to your relaxed maintenance schedule of haul outs.