When the gale was approaching, we hove to and settled in to ride out the storm. Since we were not going to be sailing for the next few days, and instead simply drifting through the water sideways, I lifted the paddle out of the water on our windvane. This presented extra stress to the Monitor windvane and led to the following failure.

Had the storm been as predicted, blowing only 20-30 knots, no damage would have occurred. The storm increased in intensity and duration, building to 40-45 knots for several days. During this time, various rouge waves bypassed the slick and broke onto the boat. These waves imparted a furious amount of energy onto the boat and all of its equipment.

The Monitor windvane was hanging out on the stern with the paddle raised high to avoid being pressured by water as we drifted laterally. The issue was these powerful breaking waves would slam into the paddle and cause incredible stress in the form of shock loads onto the equipment.

Through out the storm, only one piece of the Monitor windvane broke. Thankfully it was an easy piece to replace, but sadly it rendered the entire unit inoperable until the part was replaced.

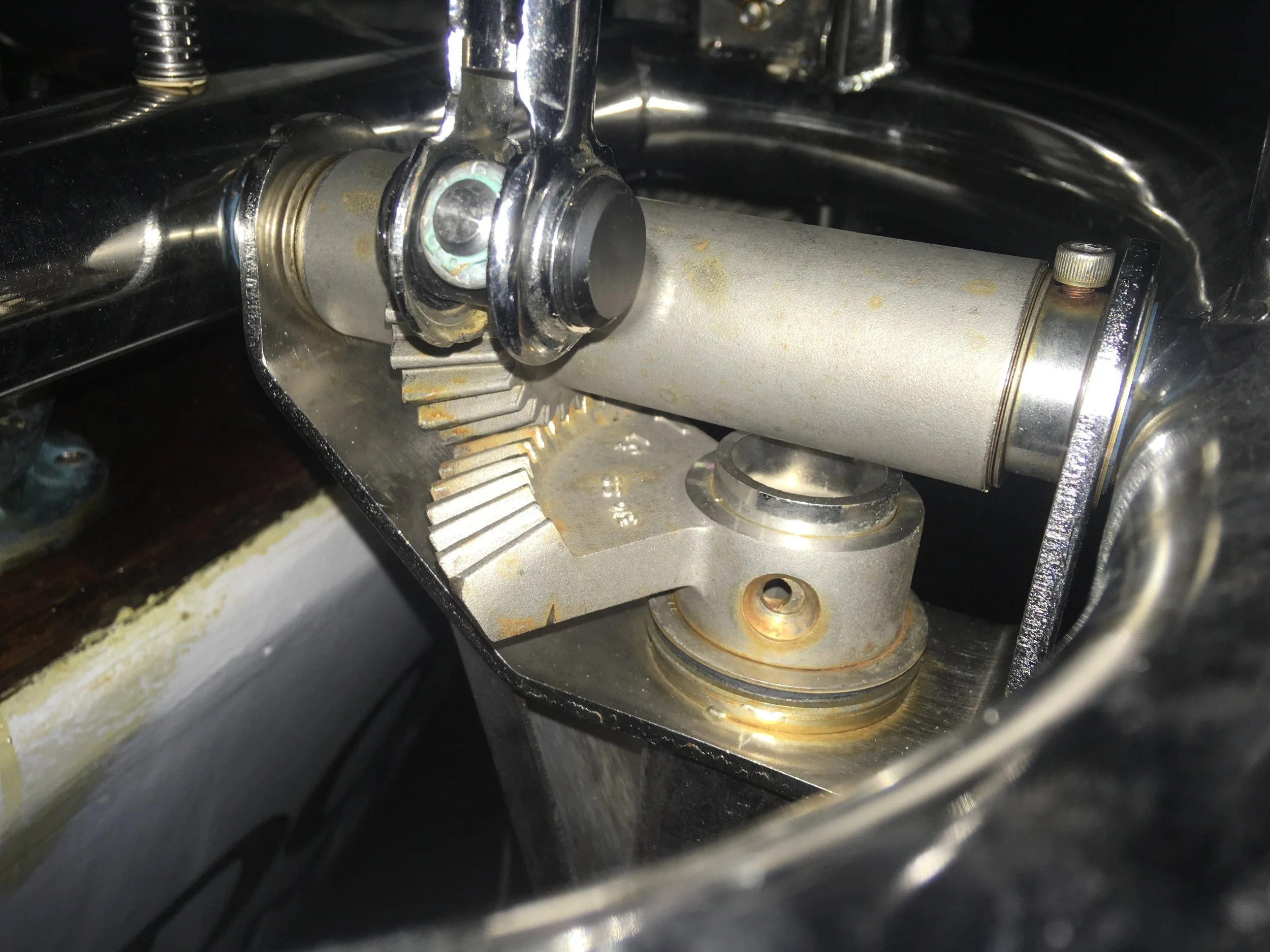

The head of a 1/4 inch stainless steel bolt sheared off! This caused the lower gear of the unit to rotate slightly and allowed the entire unit to come undone. While out in the storm, I was not able to look at everything closely enough to determine the problem, so I hand steered for over a day to get us back to shore. Once in the safety and tranquility of a safe harbor, I gave the unit a much closer inspection and located the problem.

Luckily, there was a hardware store within walking distance of the boat and the replacement bolt was had for only $0.55! I used a rubber mallet to tap the gear back into alignment with the shaft and the bolt hole so that I could easily slide the new bolt through the hole.

I then called the company because I was unsure about how the gears should interact, as in which teeth of the top and bottom gears are supposed to rest on. You see, when the bolt sheared and the lower gear rotated slightly, it then allowed the top gear to slip out of place! When I first looked at it, the top gear was facing up and was not contacting the bottom gear at all. I noticed the small arrow on the bottom gear pointing at the first groove and figured that must be there to indicate something.

Upon speaking with the owner, that arrow points to the groove that the left most tooth of the top gear is supposed to rest in as the gears first come together. With that knowledge I was able to get the unit put back together and calibrated, giving me the ability to leave it in charge of steering us on our next ocean voyage.

One thing that is still unclear is how the paddle should be placed during a storm. If you leave it down while hove to, it will be under intense lateral stress as you drift through the water. If you raise it up, the paddle is no longer under the same stresses, but any impact to it will be accentuated by the long lever arm it has created. The manufacturer told me that they are not yet completely certain which configuration is best for a storm which has led me to my next decision.

If the weather is calm enough before the storm, I plan to climb out on my stern and remove the paddle from the unit. If the paddle is not there, then it doesn't matter if it is up or down! The paddle and the air blade are the two largest surfaces of the unit, and if they are removed, the remaining structure will be able to live out the storm without fear or risk of damage.